Pump Manufacturers & Suppliers

Everything You Need To Know About Pumps

Here at Midwest Valves and Controls, we’re proud to work with some of Australia’s leading pump manufacturers. For us, it’s all about quality over quantity. That’s why we’ve spent years building meaningful relationships with our suppliers to ensure our customers get top of the range products at competitive prices. Discover more about our pumps and pump manufacturers below.

Midwest Valves And Controls: About Our Chosen Pump Manufacturers

As an Australian business, we understand how important it is to support other Australian companies, which is why much of our equipment is manufactured right here onshore. We stock equipment and spare parts from the best manufacturers in the industry. They are:

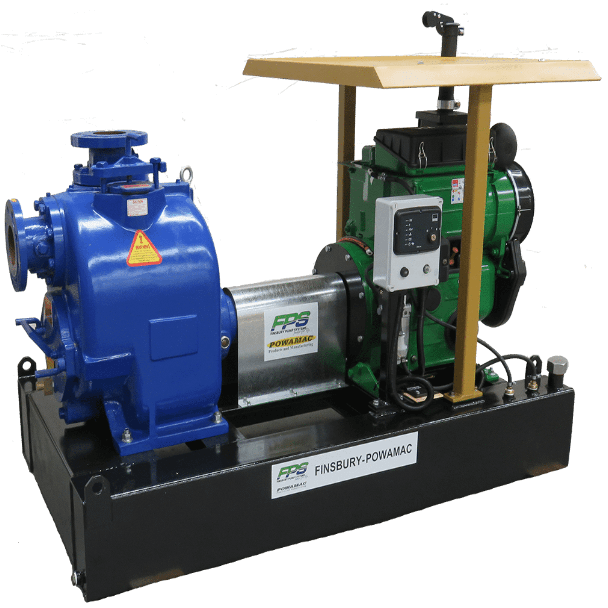

- Finsbury. Australian owned and operated since the 1940s, Midwest Valves and Controls is proud to have Finsbury onboard as one of our trusted manufacturers. Located in Adelaide, all of our Finsbury pump systems are manufactured and quality tested at their warehouse. Their dedication to providing their customers with only the best products is why we choose to work with them. So if you’re after pump advice for the mining sector, Finsbury has all the technical information you need.

- Orange Pumps. Water pumps are Orange Pump’s specialty, building exceptionally engineered and high-performing products that last. At Midwest Valves and Controls, we’ve built a strong relationship with Orange Pumps, stocking and supplying a variety of their products.

- Pentair Onga. Water movement specialists, Onga, has been supplying Australia with quality products for more than four decades. We stock a variety of Onga pumps and can supply our customers with after-sales services anywhere in Australia.

- Seepex. Founded in Germany almost 40 years ago, Seepex pumps can be used in practically any industrial industry sector.

- Southern Cross. With a focus on manufacturing water handling equipment, Southern Cross pumps have been produced in Australia for over 100 years.

- Aussie Pumps. Inspired by Australia’s extreme climate, Aussie Pumps use their equipment to provide solutions to help combat the country’s harsh conditions.

A Beginner’s Guide To All Things Pumps

If this is your first time purchasing a pump, you’ll likely need some assistance. So, we’ve developed a beginners guide to help get you started.